Walrus Cutting Board Oil – 8oz Walrus Oil

$ 13,95 $ 8,37

Our Cutting Board Oil is 100% Food-Safe and free of toxins and synthetics, designed for new builds or for reconditioning. And finally a heavy-duty cutting board oil that doesn’t require multiple coats! It will leave your board with a silky smooth finish, rich colour, and a little shine. The perfect ratio of ingredients locks in the natural wood tones while repelling water and food particles when in use. And it only takes seconds to apply.

- Semi-Gloss Finish

- For New or Restoration Projects

- Not Scented

For New Wood Projects

When using our Cutting Board Oil for new wood projects, be sure to sand at 320 to 600. To prevent raised grain, before sealing some woodworkers will do the sand-wet-sand method, meaning they’ll sand the board, wet it, let it dry, and then do a final sand before applying a finish.

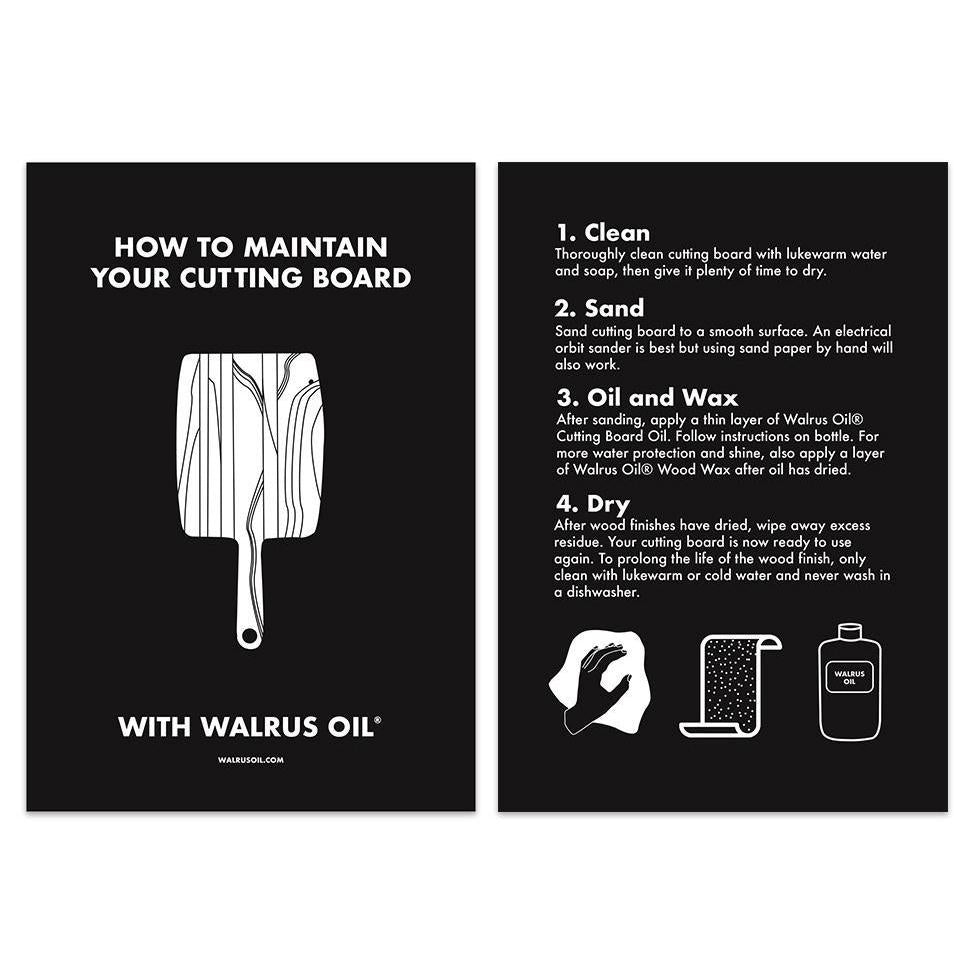

How to Maintain or Restore a Cutting Board

Cutting board maintenance and restoration is relatively simple. Clean the cutting board first with light soap and lukewarm water, then allow plenty of time to dry. If there are deep knife cuts or if any mold is visible, sanding the board down will be necessary using an electric orbit sander or planer if available. After sanding all surfaces simply apply a coat of our Cutting Board Oil and allow it to dry for 12 to 24 hours. Wipe away any excess oil after cure time.

Safe for Food-Contact Surfaces

Every product manufactured by Walrus Oil is 100% Food-Safe. All ingredients are considered GRAS (generally regarded as safe) by the FDA for food-contact surfaces. Our Cutting Board Oil can be used on kitchen butcher block counters, cutting boards, wood utensils, and even baby toys.

Using Cutting Board Oil with Another Company’s Products

Our Cutting Board Oil can be used in conjunction with most other oil-based finishes or epoxy and resins, such as when making a “river board” or when using wood pieces that have had cracks and holes filled with epoxy.

Professionally packed and fast shipping

Our long-standing partnership with UPS FedEx DHL and other international carriers allows us to offer a range of shipping services. Our warehouse staff will package each item according to our strict requirements. Your goods will go through an exhaustive inspection and adequately secured before being delivered. We ship to thousands customers each day from multiple countries. This is an indication of our dedication to being the largest online retailer globally. Warehouses and distribution centers can be located throughout Europe as well as the USA.

Note: Orders that contain more than one product are assigned a specific processing period based on the individual product.

Prior to shipment Our team will conduct a thorough inspection on the products you ordered. The majority of orders are shipped within 48 hours. Expected delivery time is between 3-7 days.

Returns

The stock is constantly changing and not fully managed by us due to the involvement of multiple entities, including the factory as well as our warehouse. Therefore, the actual inventory could change at any time. It's possible that the stocks could be depleted after your order has been placed.

Our policy lasts for a period of 30 days. If 30 days have passed by since your purchase however, we're unable to give you a refund or exchange.

To be returned the item must not be opened and in the same condition as when you received it in. It should also be in the original package.

Related products

Jigsaw Blades

Featherboard

Replacement Cutter

Easy Wood Tools 12407 Ci7 Diamond Carbide Replacement Cutter Easy Wood Tools

Wood Finish

Jigsaw Blades

Replacement Cutter

Easy Wood Tools 4400 Ci0 Round Carbide Replacement Cutter Easy Wood Tools

Jigsaw Blades

Wood Finish

Jigsaw Blades

Jigsaw Blades

Jigsaw Blades