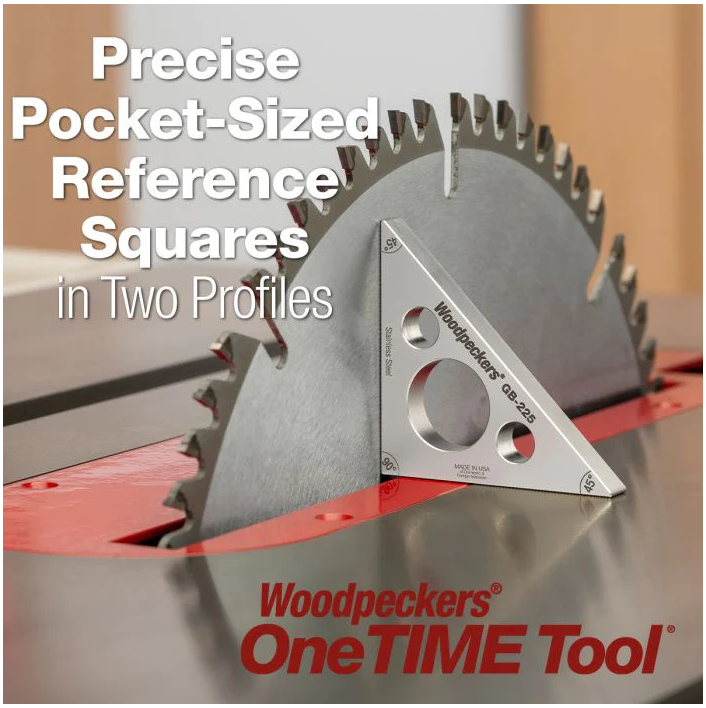

Woodpecker’s OneTIME Tool: Stainless Steel Gauge Blocks Woodpeckers

$ 145,00 $ 58,00

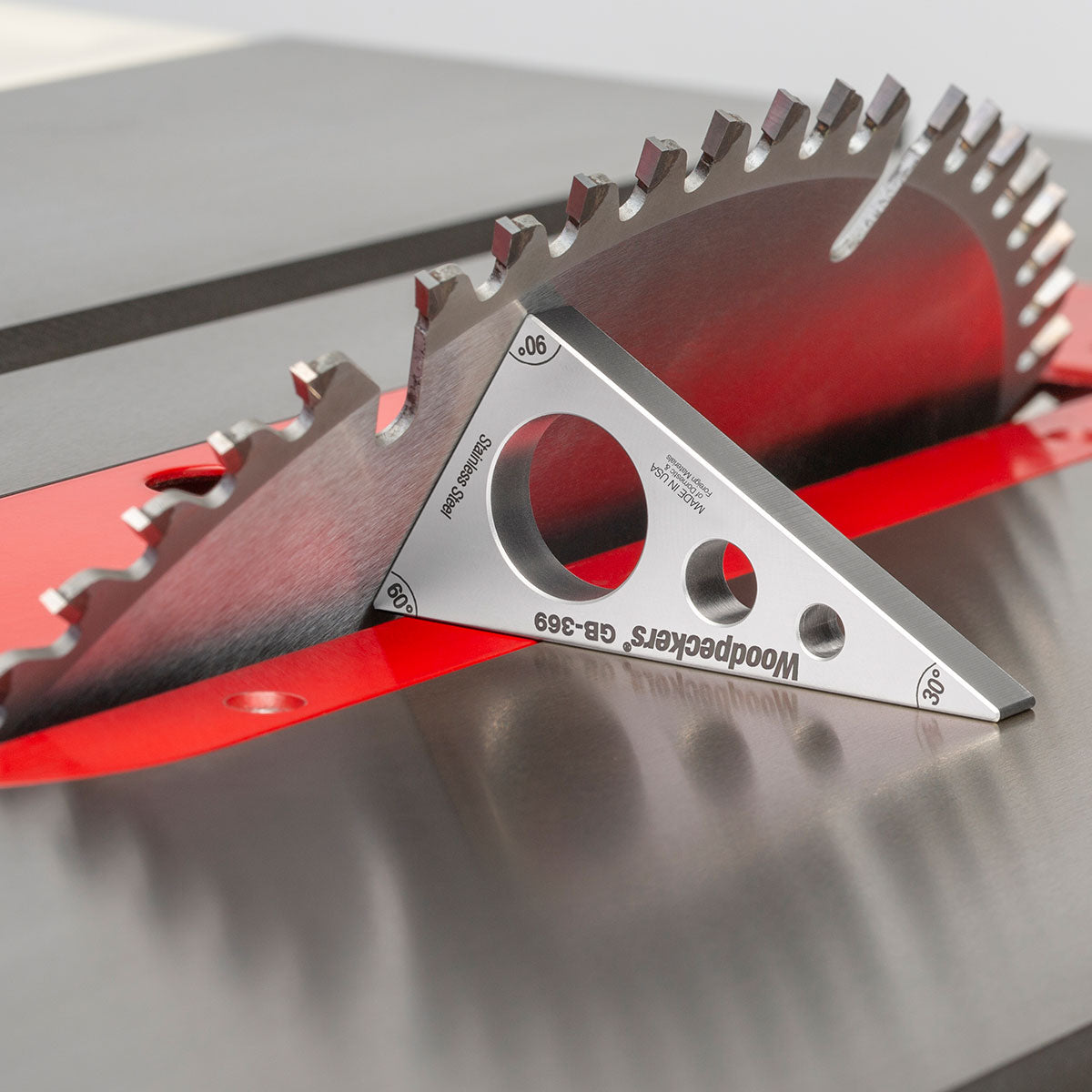

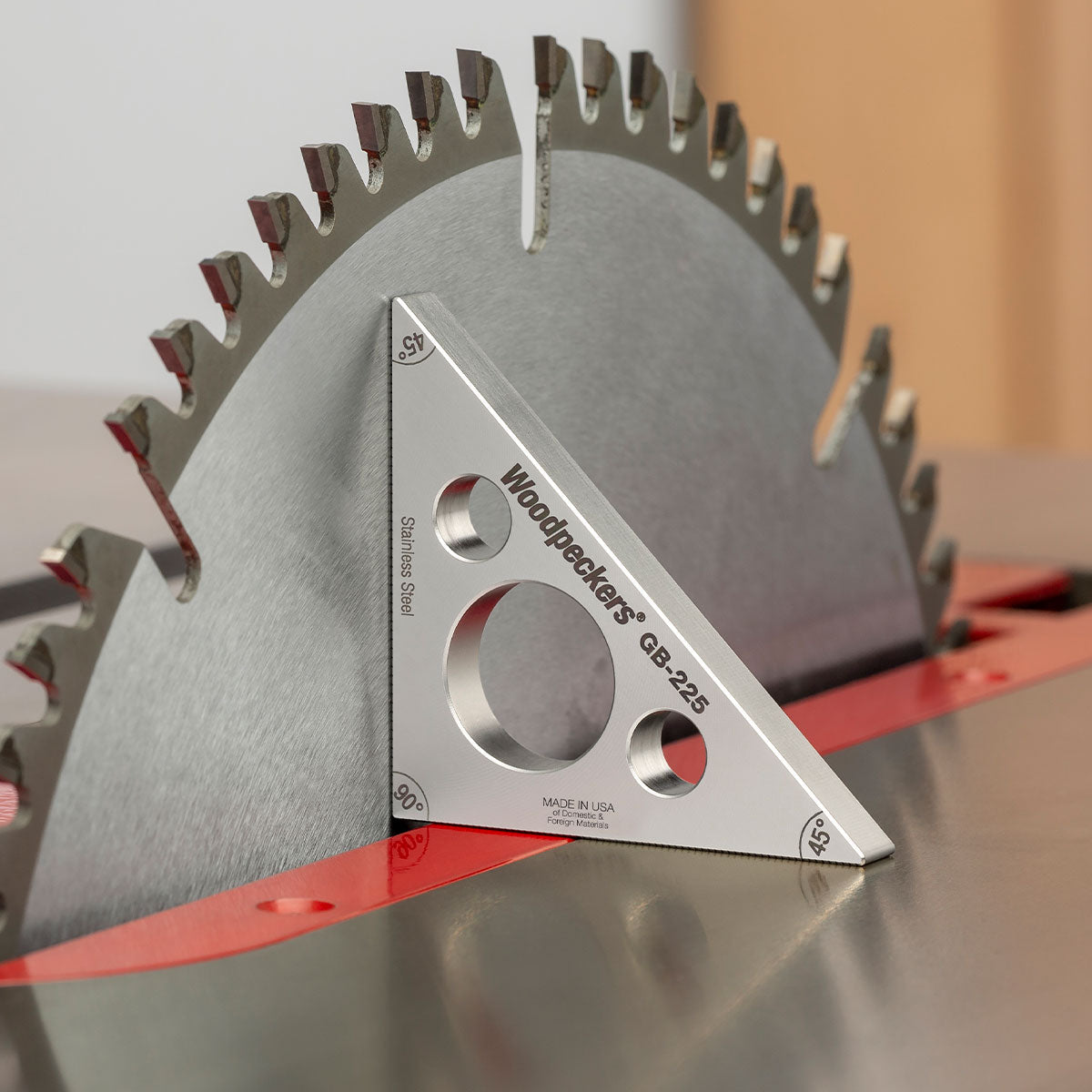

Everyone who has relied on the protractor scale of a power tool once has learned not to do it a second time. They are notoriously inaccurate, regardless of brand, cost or age. But big bulky squares have their problems when it comes to machine set-up, too. Woodpeckers latest OneTIME Tool® solves the problem with highly accurate angles machined into a pair of squares sized to fit perfectly next to blades and bits. Plus, they made them thick enough to stand up on their own – leaving your hands free to adjust and lock your machinery. Gauge Block 225 gives you perfect 45° and 90° angles and Gauge Block 369 gives you 30°, 60° and 90° angles.

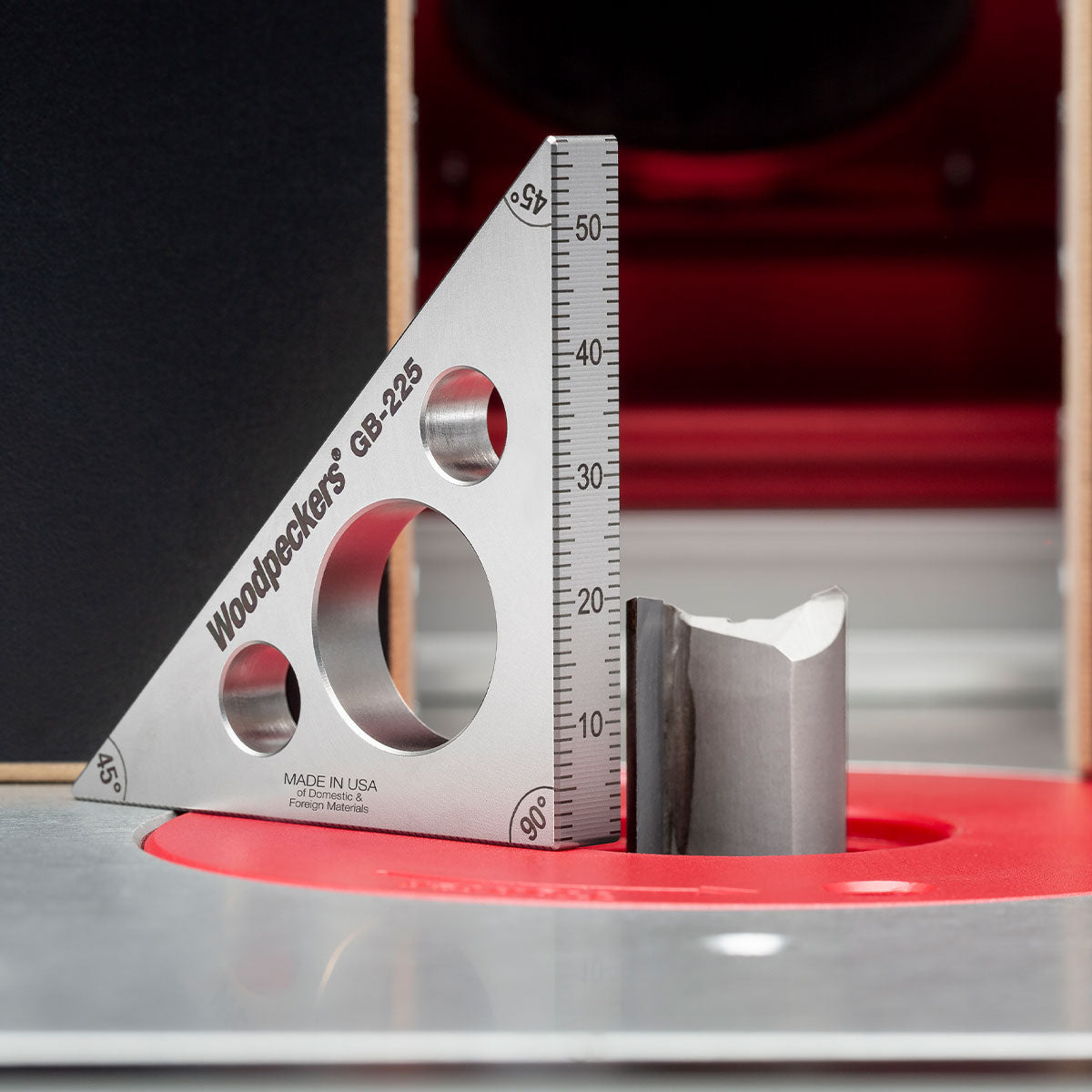

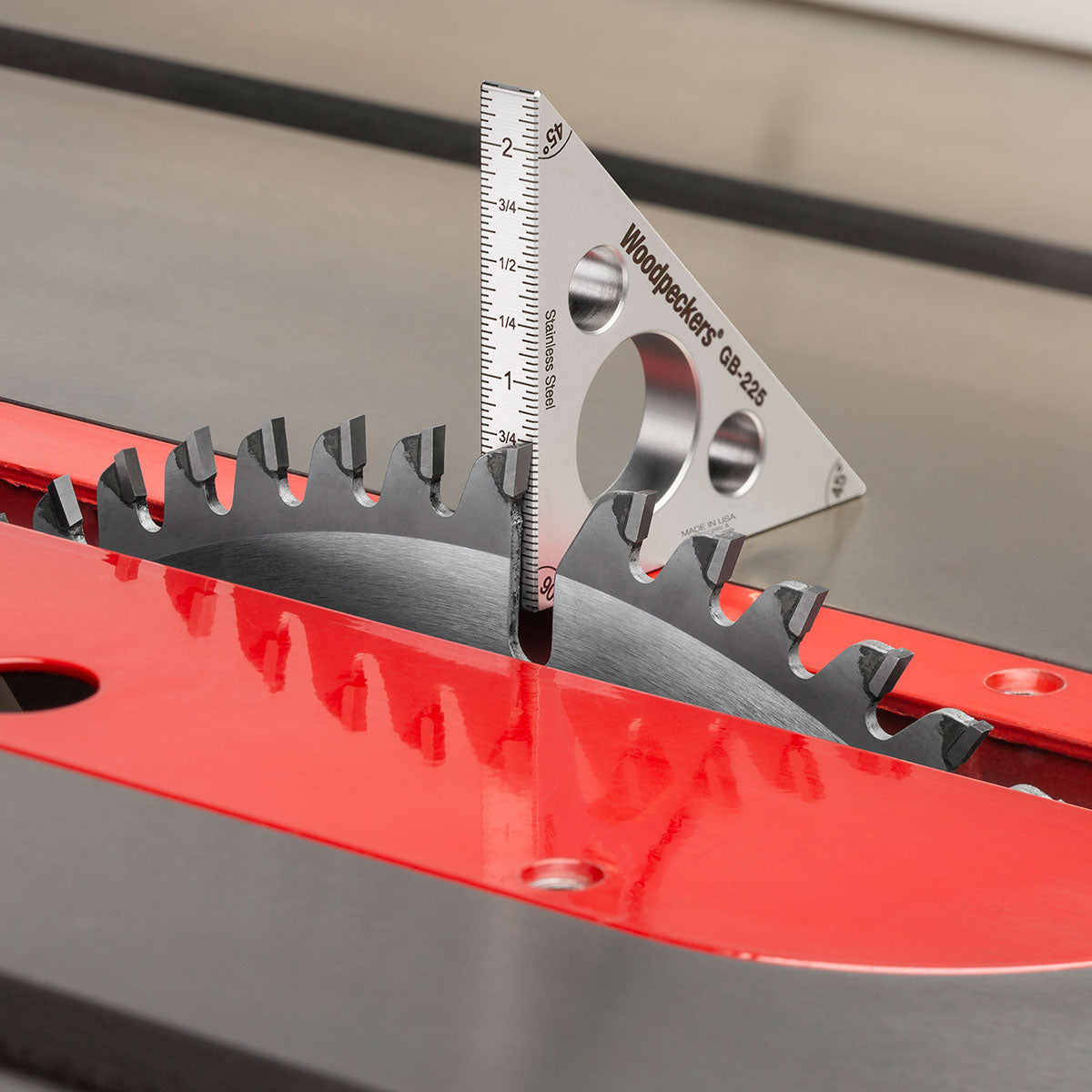

Gauge Block 225 also has wscales on both edges (one inch and one metric) that are perfect for setting the depth of cut on a saw blade, router bit or drill. The edges are 2-1/4″ long giving you ample room to check angles or set depth of cut without interfering with guards, guides or fences.

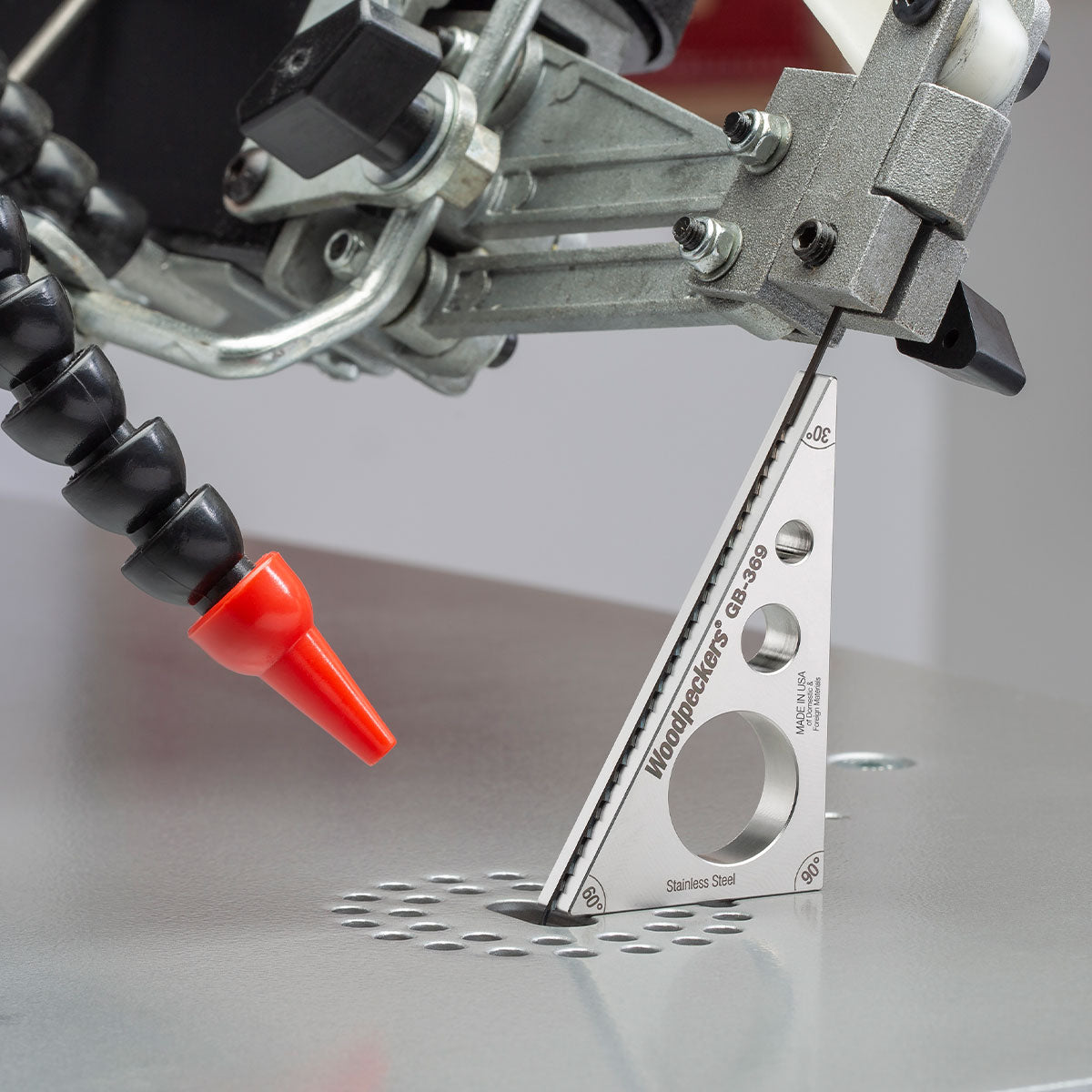

Gauge Block 369 is 1-5/8″ x 2-3/4″. With the long leg a half inch longer than the GB-225, it gives you a better reference when setting band saw or scroll saw tables. The angles on the GB-369 make it simple to set up for hexagons and equilateral triangles. In addition to machine set-up, you’ll find these little squares ideal for checking inside corners of small work like drawers and jewelry boxes.

Both Gauge Blocks are precision machined from a solid chunk of stainless steel. They’re 3/8″ thick, allowing them to stand on their own and giving them a solid feel in your hand. All the edges are gently eased and the surface features a satin finish that makes the scale easy to read and won’t glare when you’re checking blade angles. You can buy either the GB-225 or the GB-369 individually or be ready for every machine set up and save yourself a few bucks by getting the set.

Like all Woodpeckers OneTIME Tools®, the Gauge Blocks are only made to order, precisely machined and carefully inspected in their Strongsville, Ohio manufacturing facility. The deadline to order yours is January 15, 2024. Once orders are filled, the tool will again be retired from the product line. Delivery is scheduled for late February, 2024.

| Size | GB225 and GB369 Stainless Steel Gauge Block Set, GB369 30/60/90 Stainless Steel Gauge Block, GB225 45/90 Stainless Steel Gauge Block |

|---|

Professionally packed and fast shipping

Our long-standing partnership with UPS FedEx DHL and other international carriers allows us to offer a range of shipping services. Our warehouse staff will package each item according to our strict requirements. Your goods will go through an exhaustive inspection and adequately secured before being delivered. We ship to thousands customers each day from multiple countries. This is an indication of our dedication to being the largest online retailer globally. Warehouses and distribution centers can be located throughout Europe as well as the USA.

Note: Orders that contain more than one product are assigned a specific processing period based on the individual product.

Prior to shipment Our team will conduct a thorough inspection on the products you ordered. The majority of orders are shipped within 48 hours. Expected delivery time is between 3-7 days.

Returns

The stock is constantly changing and not fully managed by us due to the involvement of multiple entities, including the factory as well as our warehouse. Therefore, the actual inventory could change at any time. It's possible that the stocks could be depleted after your order has been placed.

Our policy lasts for a period of 30 days. If 30 days have passed by since your purchase however, we're unable to give you a refund or exchange.

To be returned the item must not be opened and in the same condition as when you received it in. It should also be in the original package.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Amana 51460 CNC Spiral for Steel & Stainless Steel 1/8 Dia x 3/8 x 1/4 Shank Up-Cut Amana

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Amana 45527 Carbide Surfacing, Rabbeting, Planing, Leveling 2″ Dia x 1/2 x 1/2″ Shank Amana

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized