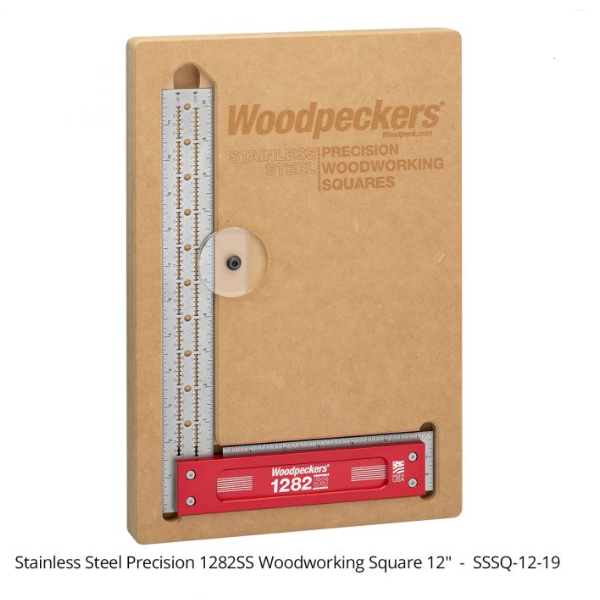

Woodpeckers 1282SS 12″ Stainless Steel Woodworking Square Woodpeckers

$ 249,00 $ 99,60

The heart of the design is a one-piece core. Square isn’t determined by pins, rivets, screws or spot-welds like it is in virtually every other square on the market. It’s determined by Woodpeckers state-of-the-art CNC milling centers. The core is machined square by a computer and verified square by their computer-controlled optical inspection system, which is capable of measuring angularity to 5 decimal places. The 1/16″ thick blade gets heat treated and tempered ensuring strength and stability. Finally, they’re bead blasted to create a non-glare finish that contrasts nicely with the laser-engraved scales.

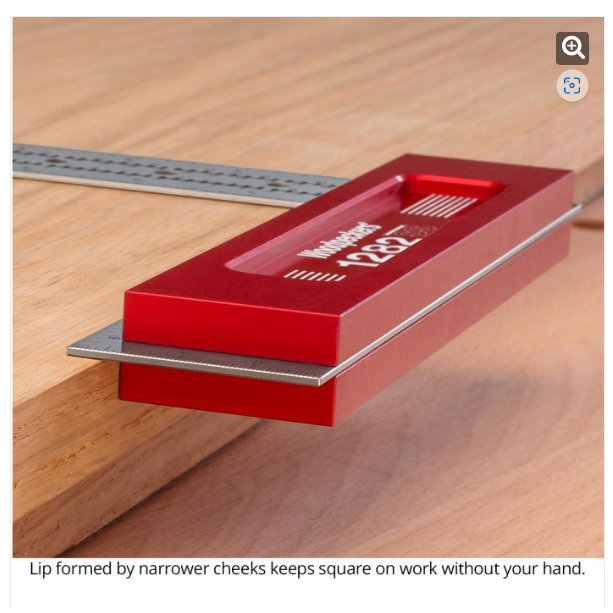

Like Woodpeckers aluminum squares, the cheeks added to the central core are narrower, forming a shoulder that keeps your square registered to your stock even when you let go. You’ll love using the new stainless-steel squares for lay out work. First, the scales are laser-engraved to a tolerance of ±.004″. The thin blade puts the scale right next to your work, reducing parallax error. And, we laser cut precisely-spaced scribing notches along the blade. Just drop a pencil into the notch of your choice and slide the square along the edge of your stock. With twin points for each notch, it doesn’t matter whether you push or pull, you’ll get a line perfectly parallel to the edge.

To aid machinery set up, Woodpeckers laser engraved the end of the beam, as well as the edges. The squares stand upright without a hand, giving you both hands to dial in the height of your router bit, saw blade or dado stack. Also like their aluminum squares, they stand behind these squares for the life of the tool. They’re guaranteed to be within ±.0085°. To put that in perspective, on the 1282SS, the maximum error you could find at the far end of the square would be about half the thickness of a human hair. If you ever find it outside that tolerance, they’ll fix it or replace it.

Professionally packed and fast shipping

Our long-standing partnership with UPS FedEx DHL and other international carriers allows us to offer a range of shipping services. Our warehouse staff will package each item according to our strict requirements. Your goods will go through an exhaustive inspection and adequately secured before being delivered. We ship to thousands customers each day from multiple countries. This is an indication of our dedication to being the largest online retailer globally. Warehouses and distribution centers can be located throughout Europe as well as the USA.

Note: Orders that contain more than one product are assigned a specific processing period based on the individual product.

Prior to shipment Our team will conduct a thorough inspection on the products you ordered. The majority of orders are shipped within 48 hours. Expected delivery time is between 3-7 days.

Returns

The stock is constantly changing and not fully managed by us due to the involvement of multiple entities, including the factory as well as our warehouse. Therefore, the actual inventory could change at any time. It's possible that the stocks could be depleted after your order has been placed.

Our policy lasts for a period of 30 days. If 30 days have passed by since your purchase however, we're unable to give you a refund or exchange.

To be returned the item must not be opened and in the same condition as when you received it in. It should also be in the original package.

Related products

Router Bits

Amana 46172-K “Spektra” Solid Carbide Compression Spiral – 3/8″ Diameter w/ Bushing Amana

Router Bits

Amana 51405-K “Spektra” Solid Carbide Spiral ‘O’ Flute For Plastics – 1/4″ Diameter Amana

Quick Clamp